Selecting the right pump

Depending on the application, you may require additional data. Feel free to contact us – we are happy to assist in the designing process.1. Data for pump design

The following parameters are required for designing and selecting pumps:- Required operating pressure

- Desired pump capacity at operating pressure

- Available air drive pressure

- Medium

- Temperature of the medium

- Ambient Temperature

2. Required operating pressure and pump capacity

Specifications of pump operating pressures are essentially based on an air drive pressure of PL = 10 bar (145 psi). The operating pressure (PB ) can be determined by multiplying the pressure ratio of the pump (i) by the available air drive pressure (PL) PB = i × PL.

Specifications of pump capacity at the respective outlet pressure can be found in the pump capacity tables following the information about our pump series featured in the catalogue.

3. Medium

The pump model should be selected to match the medium to be pumped, as it is the properties of this medium which determine the requirements for the sealing materials and the wetted parts.

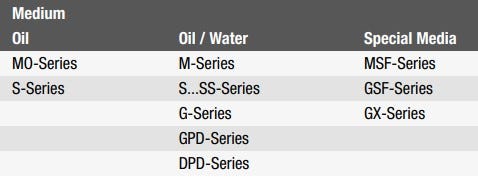

Maximator pumps are suitable for a large variety of media. Standard designs are available for oil and water and for many special media.

If your medium is not included in the Media compatibily guide, we will check suitable combinations for you.

4. Dimensions and weight

Some applications require special pump dimensions and weights. Please refer to the tables and option lists for our pump series for more information about this as well as on the availability of the „side inlet“ option.Medium, sealing variants and media compatibily

The selection of a pump essentially depends on the fluid used and the resulting specific requirements on the material of the wetted parts and sealing materials.

Maximator high-pressure pumps are suitable for various fluids. Standard pumps are available for the two most important media, oil and water.

- Seal versions for specific media can be found in the Media compatibily guide

Mode of action of the Maximator pumps

Maximator pumps are available in single- and double-acting designs.

Double-acting pumps increase flow rate by approximately 50 percent compared to single-acting pumps and have reduced pulsation by an equivalent amount.

Single-acting

Single-acting  Double-acting

Double-actingOptions and description

More information about available options and descriptions can be found here.

Pressure ratio & Number of air drive pistons

The compression ratio of the pump (ratio of area between air drive piston and high pressure piston) can be approximately derived from the type designation of the respective pump.

The G 35, for example, has a transmission ratio (i) of 1:40 and reaches a maximum operating pressure (pB) of 240 bar at an air drive pressure (pL) of 6 bar.

Depending on the series, the following model variants are available:

One-air drive

One-air drive  Two-air drives

Two-air drives  Three-air drives

Three-air drivesMaximator pumps with two or three air drive pistons achieve 2 or 3 times the operating pressure at the same drive pressure.

These pumps can be identified by the suffix -2 or -3.

Productkey

The product key of Maximator pumps largely indicate the transmission ratio of the pump and include information on the seal version and other options.

Product group Pressure ratio Air drive parts single/double-acting

MO Numbers -2 or -3 D

S

M

GSF

...Example: M 111-NPT-LTA-HL-SGD

M 111 - M series pump - pressure ratio 1:130

NPT - connection with NPT thread *

LTA - modification for low ambient temperatures

HL - Hand lever

SGD - Special gas operation (For applications with special drive gases)

* more information about connections and threads can be found here

Temperature

The operating temperatures of Maximator pumps range from -20°C to +80°C as standard. The pumps with seal version -VE for water operation can be used up to +60°C, and temperatures up to +80°C are possible for short-time duty.

Further temperature options for use in other temperature ranges can be found here.

Didn't find the information you were locking for? Something is still unclear for you? We will be happy to help you. Simply use the contact form.